Practical,

at last,

for the common plant:

Pain-Free Proven Productivity Previously Prescribed to Prestigious, Privileged Powerhouses

Half of manufacturers fall below average in any given category:

Revenue,

Margin,

Quality,

On Time Delivery.

Only because.. that’s how averages work.

There’s only one place where all the children are above average - Fictional Lake Wobegon.

It’s true, everyone can excel at what they do, but that just moves the average. The distinction will remain.

But if your direct competitors are better at quality and delivery in this Age of Amazon, your smartest customers may begin to shop around.

Large companies stay above average because they spend the most time and money on improvement.

They have specialists, consultants, and huge, sophisticated continuous improvement systems. Smaller factories just do not have that kind of support.

The gap grows, even when smaller teams are working just as hard.

Operational excellence isn’t about squeaky clean floors and motivational posters on walls.

Excellence in manufacturing opens doors.

It lowers costs, it enables throughput gains, it helps to capture more customers.

And when they save more, earn more, and get more customers, they can invest more into getting even better tomorrow.

This creates two groups in the industry:

Plants with constant care and attention

Plants doing their best without enough resources

It is like one kid going through life always getting full doctor’s office checkups and regular sick care, while another tries to cure themselves of every symptom they’ve typed into WebMD with whatever they have in the cabinet.

He’s doing everything he can with whatever he’s got.

But smaller manufacturers can still get healthy and stay healthy.

Some small plants improve every year and will keep improving over the next five years and beyond.

They do not do this with giant, complex programs.

And they do not try every new trend they see online.

They focus on what their factory actually needs.

By finding the hidden problem, not chasing every symptom, focusing on the right fix, and solving things with simplicity.

Much like a good doctor who starts with the basics and pays attention to the whole person, not just one box on the chart.

For family owned factories, this matters even more.

Your plant might be your future, your retirement, or your legacy. When work feels overwhelming, a clear diagnosis and a simple treatment plan can bring real peace of mind.

If your days are more stress than success,

If small problems keep stacking up,

If you are not sure what to fix first,

There is an answer.

And the answer is not more tools or more pressure.

The answer comes from:

clean information,

simple structure, and

habits that support real health in the plant.

Just like in our physical health, small consistent improvements can make a big difference.

We usually see two kinds of plant leaders.

Leaders who know the right next step but do not have the time or capacity to act on it.

Leaders who inherited so many problems that it is hard to know where to begin.

We designed our approach to help both.

We come alongside to confirm and diagnose; we treat, and we help sustain long-term health.

This new way of living is possible. Even for growing or struggling companies.

Smaller factories can reach high performance with:

20 to 250 employees

Under $40 million a year in sales

Limited time

No room for complex, heavy systems

Everyone’s factory life can be better, it just takes the right treatment.

It just takes getting started with the right next step. The biggest industry leaders started with one small change. Now they can afford to invest in massive, expensive improvement programs. That’s how they widen the gap every year.

But for smaller factories, the biggest problems AND the minor, common annoyances can be eliminated; creating consistent, smooth work weeks and a happier, more functional team.

What if you started with one step:

Fix What Bugs You.

This is essential. That’s where we’d start.

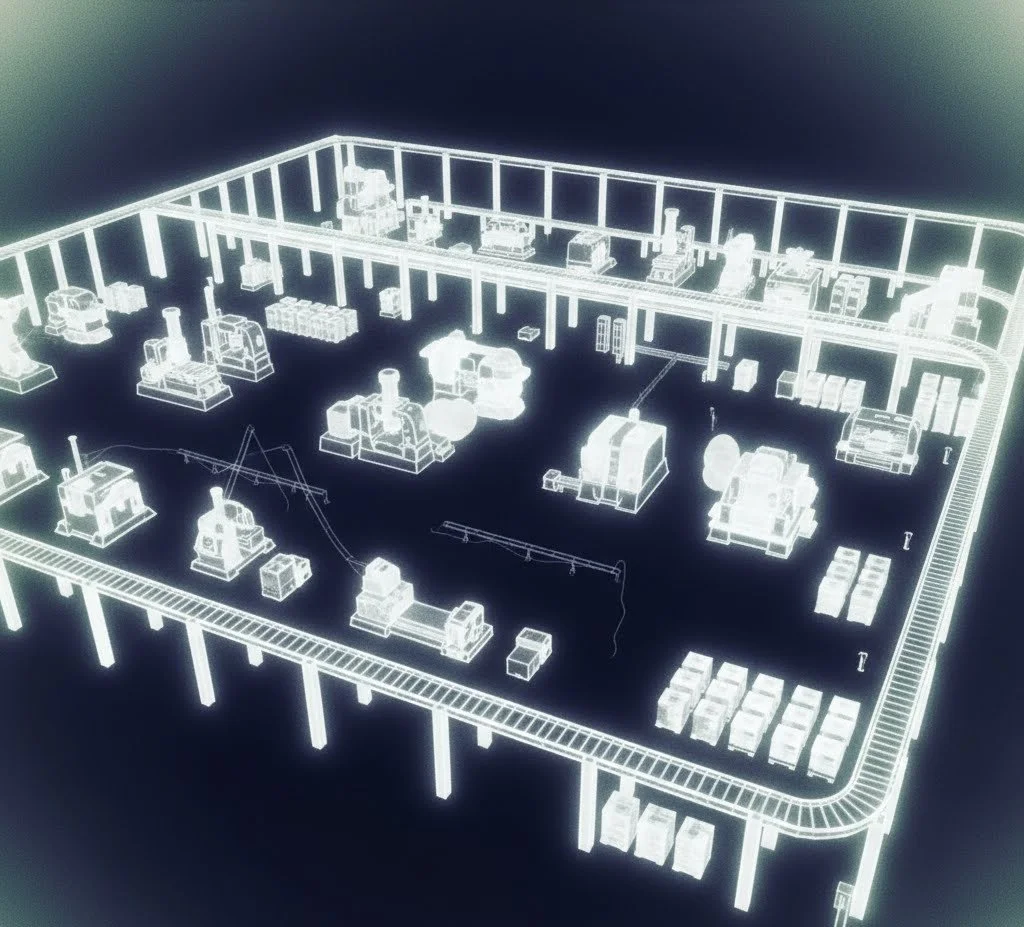

What we built

We took the entire world of continuous improvement and condensed it into a simple, strong method that fits smaller factories.

Think of it like good medicine:

Some things are helpful for everyone, like vitamins and good nutrition.

But many treatments must be specific.

We will not prescribe knee surgery for a runny nose.

Every plant gets what it actually needs.

Lake Wobegon is the fictional Minnesota town in Garrison Keillor's "News from Lake Wobegon" radio show segment, "where all the women are strong, all the men are good looking, and all the children are above average."

The factories with additional resources from past and present success are the ones who invest the most into future status.

This leaves smaller plants with less opportunity and an uncertain future.

Factory Assistance Services

-

Factory X-Ray

-

Weekly Treatment

-

-