Get treatment for all your manufacturing throughput and quality ailments.

Our services

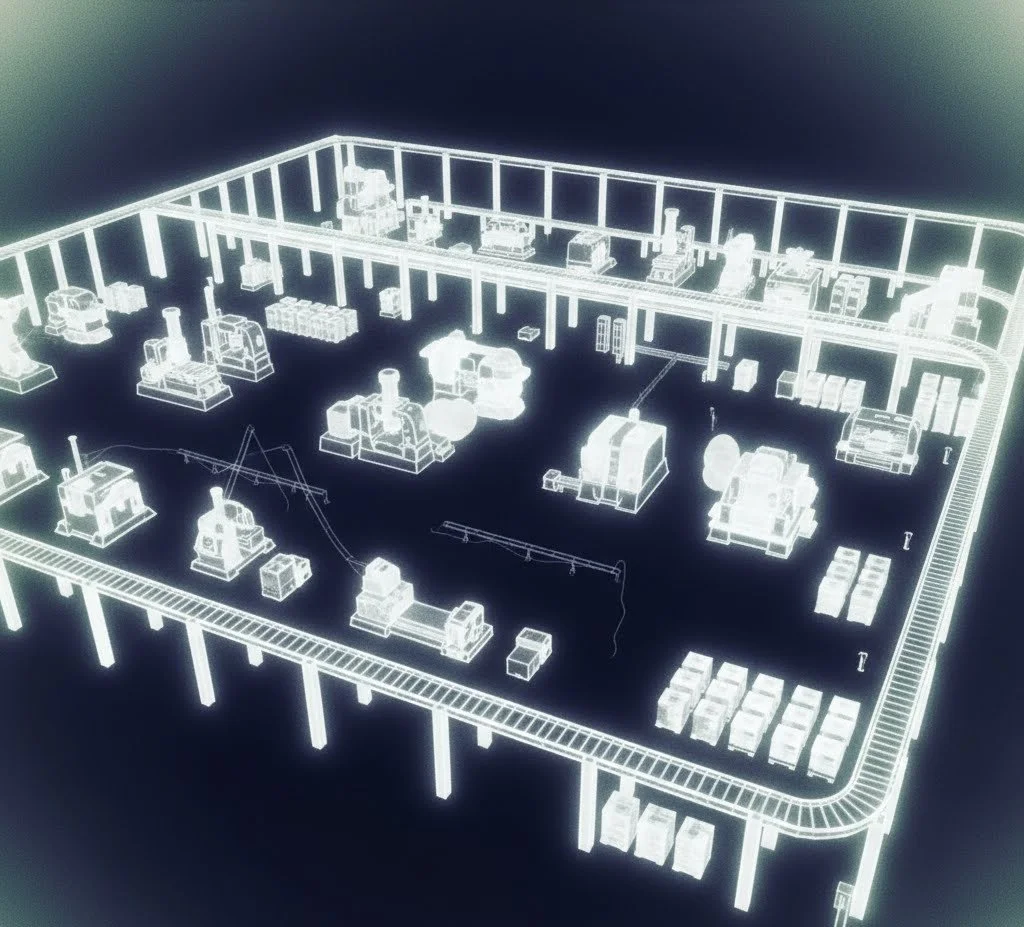

Factory X-Ray

Our Flagship Service, the Factory X-Ray is our best shot at reviving Manufacturing across Northeast Ohio, beyond just the select few privileged powerhouses.

This fast-paced diagnostic includes multiple visits spanning all critical departments and processes.

We trust but verify the facts and assumptions around the factory, drilling down into the lowest levels and darkest corners to find real causes of delays, defects, and detours.

At the end, you get your prioritized factory report with all the details on our top findings, guaranteed to uncover $50,000 in waste and opportunity losses or we’ll give back the difference to maintain our 10:1 ratio.

That’s our 10:1 Guarantee.

It’s efficient, thorough, and even surprising.

Inside, you’ll see exactly what was found to be causing the biggest delays, defects, and detours, and how much it’s costing you to keep things the way they are.

It also includes the actions we would take during our Weekly Treatments, if we were to continue. But an ongoing treatment plan is not automatic.

If we feel we are well suited to carry out those next steps, we will let you know within the Factory X-Ray report that we’d love to continue working toward your goals.

Factory X-Ray | $5,000

Weekly Treatment

After the Factory X-Ray, ongoing treatment is prescribed at $3,500 per month.

This is the affordable extended service that sets us apart from all other firms.

Instead of show up, data dump, and leave, we really want to ensure the projects are successful, the changes stick, and the gains sustain.

This provides 4-5 uninterrupted days per month where a world-class manufacturing efficiency specialist works on the next right thing.

You get:

Senior-level industrial engineering expert, specialized in manufacturing,

At a rate that wouldn’t afford half of an entry-level industrial engineer,

Focused on your operation,

Investing more time into planning and executing high-impact factory improvements than you’ve been able to dedicate in a year of:

Forecast meetings,

Interviews,

New hire no-shows,

Machine breakdowns,

“Updated” forecast meetings,

"Quick" questions at the coffee pot,

...which suddenly became a “make-or-break” 2-day side quest,

… and then, “Never Mind,”

Parts shortages,

Trainings,

Retrainings,

Explaining the new backflushing process for the third time this week,

Getting locked out of the scheduling spreadsheet,

Inventory Adjustments,

Incident Reports,

Chasing down signatures,

Purchase requisitions,

"Why isn't this on the schedule?"

Expense Reports,

Expense Report rejections, because there was a Red Bull on your Home Depot receipt,

Toolbox talks,

"Got a second?"

Finding coverage for call-offs,

(There was no coverage for the call-offs),

Supplier site visits,

Explaining why “assemblers can’t just work faster,"

Customer site visits,

Overtime Approvals,

Urgent expedited orders,

*New* Updated “Final” Forecast Meetings,

"Can you just..."

Suddenly you have a new sidekick whose only job is the slow methodical work you never have time for: Finding the real bottlenecks, writing out what actually works, tracking improvements, and asking 'what if we tried this whole step differently?'

4-5 solid days per month, focused on the methods instead of the ship dates.

Finally here are those elusive 30-40 hours devoted to the most impactful tasks that make everybody’s jobs quicker, easier, and safer.

No new vocabulary words, no belts or societies, just a focused fixer.

Per Month | $3,500

__________________________________

or with Annual Plan save $650/mo.

Annual Plan | $34,200

billed at $2,850/month

Our philosophy: creativity before capital. When we identify improvements, we'll choose free and low-cost solutions first.

But when a $50 tool will easily save you $100/month, we’re probably going to recommend the tool.

That said, we’re supposed to mention here that tool and fixture purchases aren't included in the monthly fee.

For some places we just send you a link and you can handle them through your normal purchasing process. Other places don’t want one more piece of paperwork and one more to-do for their buyer. Then we just get your approval for the purchase & itemize our invoice, so it all gets paid at once.

Either way works. Whatever we need to do to keep the tax man away.

(And yes, we've learned to keep our Red Bull on a separate receipt.)

Prescriptions & Procedures

Job Design, Ergonomics & Work Hazard studies, Ramp-Up Plans, Project Trackers, Templates, Dashboards, Visual Aids, Work Instructions, Layered Process Audits, Analysis Tools, Cell Layouts.

Generally already included as needed within ongoing Weekly Treatments.

But à la carte options exist as Add-Ons or standalone items at any time after the Factory X-Ray.

Deliverables | $75-$750 ea. Just Ask.

Manufacturers already above average are investing the most to widen the performance gap. The more market share they pick up, the less remains for the lower half.

It’s a mean, cruel world out there!

While the largest corporations employ:

1, 2, 5, or more industrial engineers per site,

plus any number continuous improvement experts and extra support staff,

plus many layers of plant managers, production managers, supervisors, directors, leads, junior leads,

plus mechanical and manufacturing engineering departments,

etc.

That’s not viable for 80% of U.S. manufacturers.

Our customers don’t have multiple automation lines and dozens of robots, 77 dedicated data analysts, 122 A.I. interns, or any other single luxury that’s just bread and butter for the big guys.

Here's the challenge most mid-sized manufacturers face:

We're competing against two different types of competitors we can't beat at their own game.

First, there are massive factories with millions of dollars in automated equipment. They can spread huge investments across millions of units, making each part super cheap to produce. Must be nice, but … boring!

Second, there are overseas factories paying workers $2 an hour instead of $25 an hour.

In a place like the Philippines, the daily minimum wage is $11.

So we aren’t going to win by trying to match their advantages. We don't have the capital to buy their level of automation, and we won’t pay workers a dollar an hour (nobody should).

The real question is: Are we making the most of what we can actually control?

Things like:

Running our processes efficiently (no extra steps or hours wasted waiting for the next batch)

Using our equipment economically - not running extra to “appear” efficient only to stock a warehouse full of 40 years of rusty garbage (been there)

Solving real problems instead of 200 sloppy workarounds moving us 1 millimeter in every direction but upward

That's where the actual competition happens for regional manufacturers.

Factory Physicians are happy to help with all that, and more.

Basically, we will do everything we can, in order to help you do everything you can.